Power Plants

Overhaul of Rotating Equipment

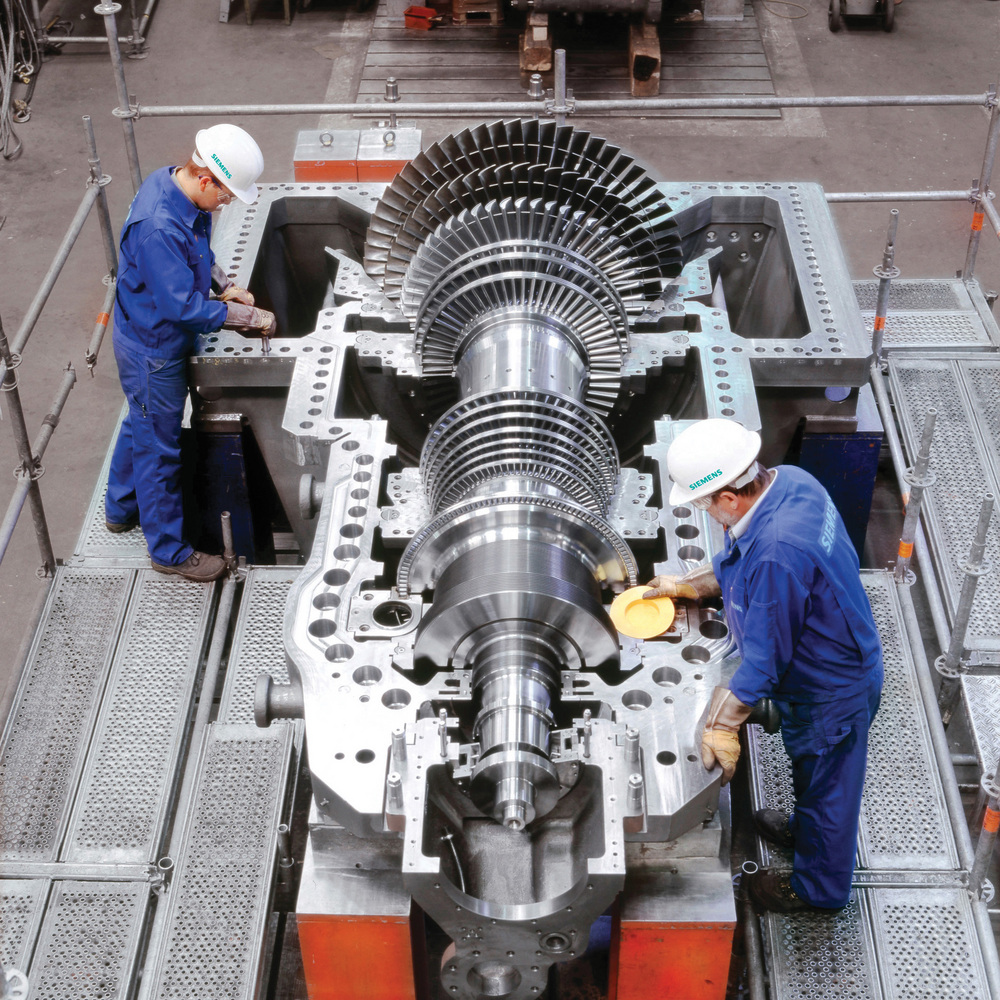

Overhauling rotating equipment in power plants is a process that involves inspecting, identifying, and repairing or replacing worn or under-performing components to restore the equipment’s performance. The goal is to extend the equipment’s life and reliability, reduce downtime, and minimize environmental impact.

Here are some steps involved in overhauling rotating equipment:

- Inspection

A thorough inspection is performed to assess the condition of the equipment and identify any issues. This may involve visual examination, measurements, and testing. - Troubleshooting

Technicians analyze the data collected to diagnose the specific problem affecting the equipment. - Disassembly

The equipment is disassembled, removing necessary components like impellers, bearings, seals, and shafts. - Component repair or replacement

Faulty components are repaired or replaced. Repair options include welding, machining, reconditioning, or surface restoration coatings. If the damage is severe or the component is beyond repair, a replacement part may be necessary.